Low density Polyethylene Film Grade QLT04 QLF39

Low-density polyethylene (LDPE) is a synthetic resin using a high pressure process via free radical polymerization of ethylene and is therefore also called “high-pressure polyethylene”. Since its molecular chain has many long and short branches, LDPE is less crystalline than high-density polyethylene (HDPE) and its density is lower. It features light, flexible, good freezing resistance and impact resistance. LDPE is chemically stable. It has good resistance to acids (except strongly oxidizing acids), alkali, salt, excellent electrical insulation properties. Its vapor penetration rate is low. LDPE has high fluidity and good processability. It is suitable for being used in all types of thermoplastic processing processes, such as injection molding, extrusion molding, blow molding, rotomolding, coating, foaming, thermoforming, hot-jet welding and thermal welding

Application

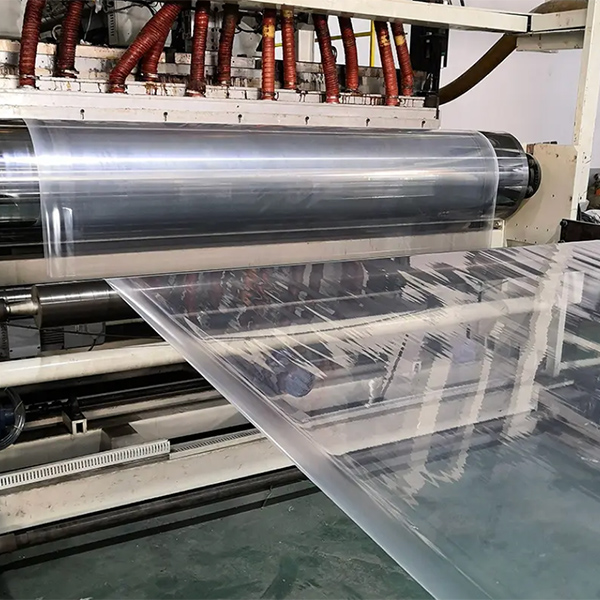

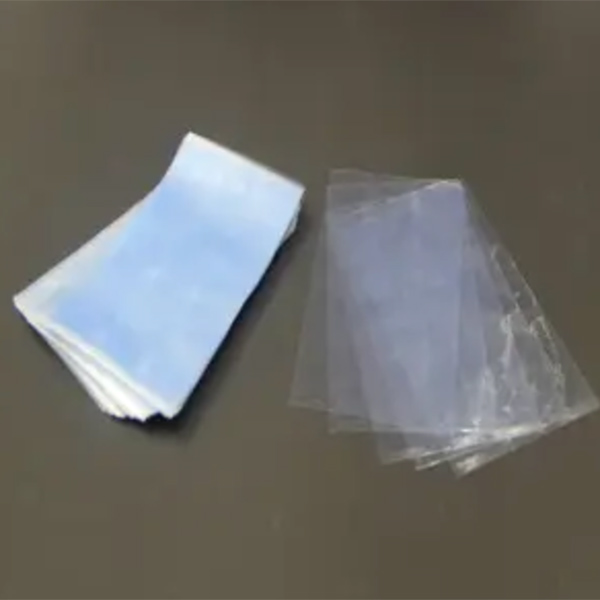

LDPE film grade is principally used in the production of blowmolding packaging film, agricultural film and can be blended with linear low-density polyethylene (LLDPE) to produce modified PE. In addition, it can be used for heat shrinkable packaging film, laminated film, freezing film, medical packaging, multi-layer coextrusion film, heavy-duty packaging film, pipe coatings, cable sheathing, lining and high-end chemical foaming.

LDPE (QLT04/QLF39) is a very good high transparent packaging film raw material.

Parameters

|

Grades |

QLT04 |

QLF39 |

|

|

MFR |

g/10min |

3.0 |

0.75 |

|

Density |

23℃, g/cm3 |

0.920 |

0.920 |

|

Haze |

% |

10 |

— |

|

Tensile Strength |

MPa |

6 |

6 |

|

Elongation at break |

% |

550 |

550 |

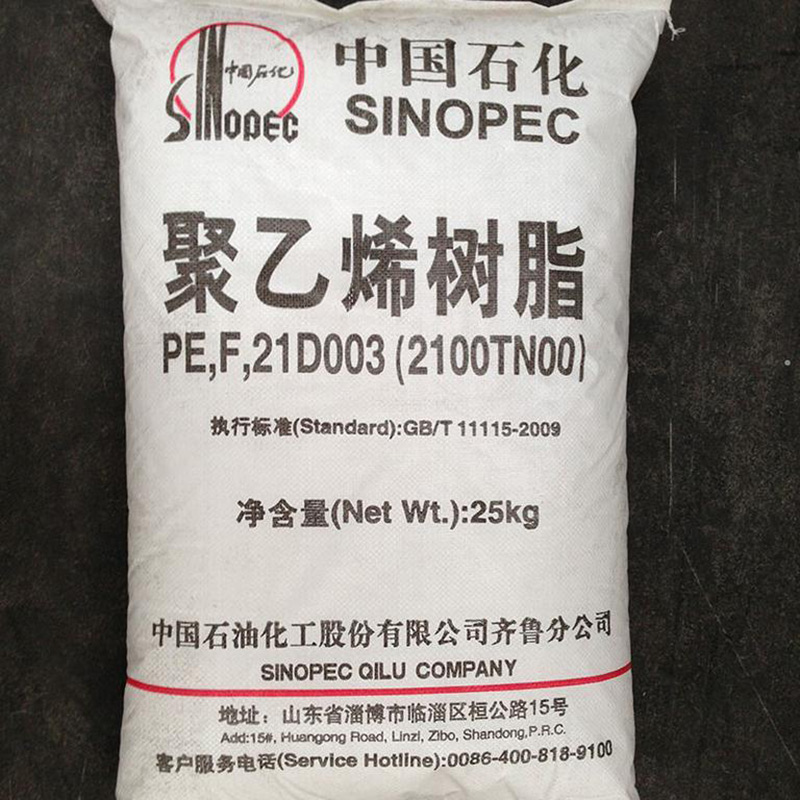

Package, Storage and Transportation

The resin is packaged in internally film-coated polypropylene woven bags. The net weight is 25Kg/bag. The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air. During transportation, the product should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.