Aluminum hydroxide is an important inorganic chemical, widely used in metallurgy, chemical industry, electric power, building materials and other industries. It has good fire resistance, moisture absorption and electrical insulation properties, and is widely used as an important raw material for refractories and electronic materials. The following will introduce the production process of aluminum hydroxide in detail.

The main production processes of aluminum hydroxide include alkali process, alumina process and alumina process. Among them, alkali process is the most commonly used production process at present.

The steps to produce aluminum hydroxide by alkali process are as follows:

1. Raw material preparation: The main raw material for the production of aluminum hydroxide by alkali process is bauxite, which contains a high alumina content. In addition, a certain mass ratio of sodium hydroxide solution is required.

2. Petrochemical reaction: Mix bauxite with sodium hydroxide solution, and heat and stir, so that the two fully react. A lot of heat will be generated during the reaction process, and it is necessary to control the reaction temperature and stirring speed to ensure the smooth progress of the reaction.

3. Precipitation: After the petrochemical reaction, the resulting aluminum hydroxide particles will precipitate to the bottom. At this time, the upper layer of solution and aluminum hydroxide particles need to be separated, usually by centrifuge.

4. Water washing: the separated aluminum hydroxide particles are washed to remove impurities and improve the purity of aluminum hydroxide.

5. Filtration: After washing, it is also necessary to filter the aluminum hydroxide particles to remove the remaining water and impurities on the surface of the particles.

6. Roasting: The filtered alumina hydroxide particles need to be further dried and roasted. First, the aluminum hydroxide particles are dried to remove excess water. Then, the dried alumina hydroxide particles are further roasted to improve their crystallinity and purity.

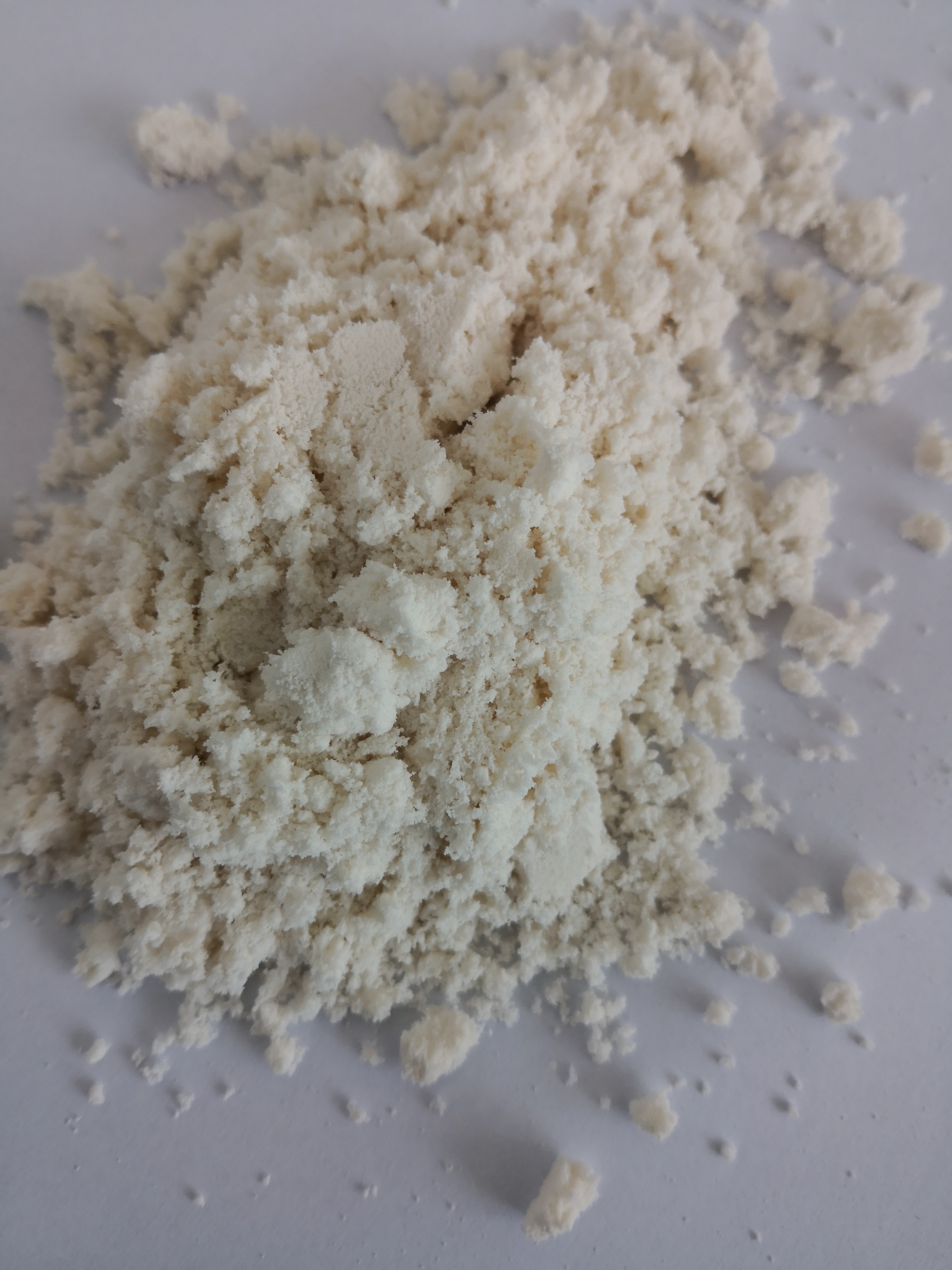

7. Grinding: After roasting, aluminum hydroxide particles will become hard and need to be crushed to achieve the required particle size.

8. Packaging and storage: Finally, the aluminum hydroxide powder is packaged and stored for subsequent use and sale.

In general, the alkali process is a relatively mature and economic aluminum hydroxide production process. However, the production of aluminum hydroxide by alkali process will produce a certain amount of waste water and waste gas, which will cause a certain pollution to the environment. Therefore, in practical applications, corresponding environmental protection measures need to be taken to reduce the impact on the environment.

Of course, in addition to the alkali process, there are other production processes, such as the aluminite process and the alumina process. The aluminite process is the reaction of molten aluminite with high temperature sodium hydroxide to obtain aluminum hydroxide, while the alumina process is the reaction of aluminum sol with sodium hydroxide to obtain aluminum hydroxide. These processes can avoid the wastewater and exhaust gas produced by the alkali process to a certain extent, but the production cost is high, so it is relatively rare in practical applications.

In summary, the production process of aluminum hydroxide mainly includes alkali method, alumina method and alumina method. Among them, the alkali process is the most commonly used process, through the petrochemical reaction of bauxite and sodium hydroxide solution to obtain aluminum hydroxide. In the production process, it is necessary to pay attention to the control of reaction temperature, stirring speed and other process parameters to ensure the quality and output of aluminum hydroxide. At the same time, it is also necessary to take corresponding environmental measures to reduce the impact of waste water and waste gas on the environment.

Zibo Junhai Chemical Co.,Ltd focus on Aluminium hydroxide sales for many years,aluminium hydroxide is widely used in the production of aluminium sulfate,poly aluminium chloride,plastic filler.

If you have any questions,feel free to contact me.Whats app:+86 15653357809

Post time: Mar-14-2024