HDPE for packaging containers

HDPE for packaging containers,

HDPE FOR hollow containers,

HDPE resins are the choice for many applications due to their resistance to cracking, rigidity and ability to withstand high temperatures and deformation. They provide a great range of properties for almost any blow moulding process for hollow bodies.

Plastic packaging is the development direction of packaging industry in recent years, especially with plastic containers to replace glass containers, steel containers have become most of the liquid

The development direction of packaging. In recent years, the proportion of vegetable oil, medicine, beverage, washing products, cosmetics and other plastic containers has been increasing.

Also led to the development of small and medium-sized packaging containers; The steel is replaced by 200 L VAT and IBC container

The pace of container is accelerating, which greatly stimulates the development of large hollow container industry. In addition, the large storage box of domestic medium and large cities, dustbin also began

With this type of cask, the demand for hollow containers will also increase

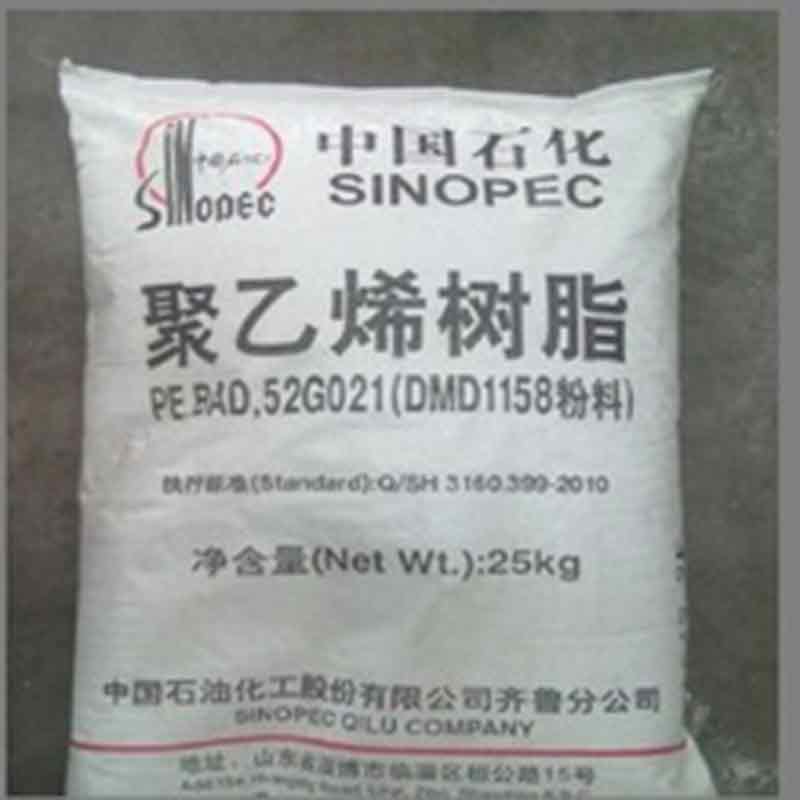

High density polyethylene resin products are granule or powder, no mechanical impurities. Thermoplastic elastomers have the physical and mechanical properties of vulcanized rubber and the processing properties of soft plastics. Because rubber is no longer thermally-vulcanized, it can be easily made into a final product using simple plastic processing machinery. Its characteristics, the rubber industry production process shortened l/4, saving energy 25% ~ 40%, improve efficiency 10 ~ 20 times, can be called the rubber industry another material and technology revolution. The two main methods of manufacturing and processing thermoplastic elastomers are extrusion and injection molding, which is rarely used. Thermoplastic elastomers are manufactured by injection molding, which is fast and economical. The injection molding methods and equipment used for general thermoplastics are applicable to thermoplastic elastomers. Thermoplastic elastomers can also be processed by blow molding, hot forming, and hot welding.

Application

DMD1158 powder, butene copolymerization product, special material for large hollow vessel, with good toughness, resistance to environmental stress cracking and good processability. Resin storage warehouse environment should be kept ventilated, dry, away from fire and direct sunlight. Open air environment should not be stacked for a long time. During transportation, materials shall not be exposed to strong light or heavy rain, and shall not be transported together with sand, soil, scrap metal, coal or glass. It is strictly prohibited to transport with toxic, corrosive and flammable substances.