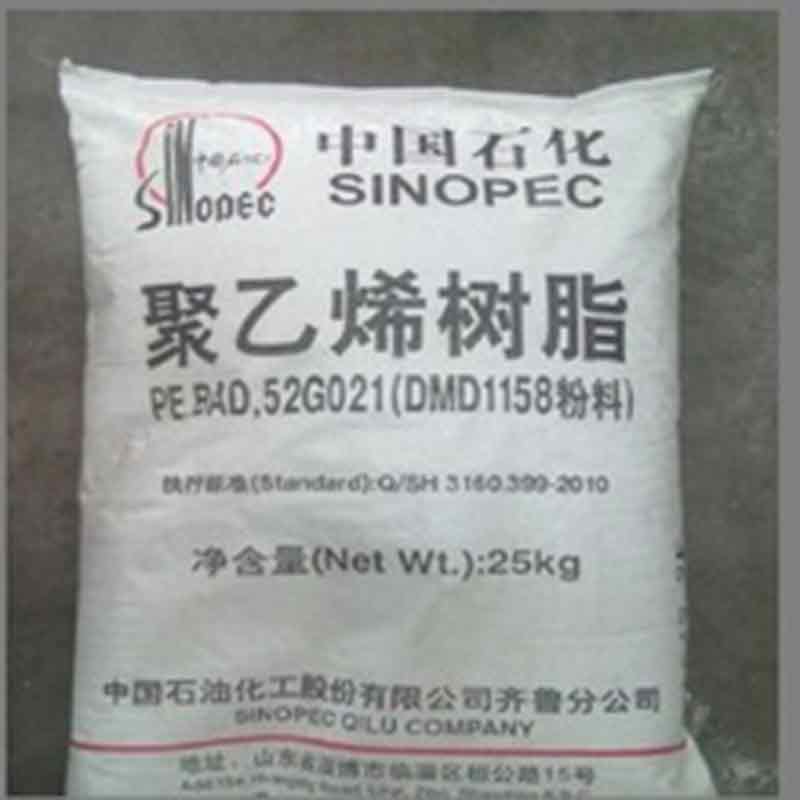

HDPE pipe grade

HDPE pipe grade,

HDPE for corrugated pipe, HDPE For Water Pipe, HDPE P100 for pipe extrusion, HDPE used in extrusion of pipe,

HDPE pipe grade has broad or bimodal distribution of molecular weight. It has strong creep resistance and good balance of rigidity and toughness. It is very durable and has low sag when being processed. Pipes produced using this resin have good strength, rigidity and impact resistance and excellent property of SCG and RCP.

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the open air. During transportation, the material should not be exposed to strong sunlight or rain and should not be transported together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is strictly prohibited.

Application

HDPE pipe grade can be used in the production of pressure pipes, such as pressurized water pipes, fuel gas pipelines and other industrial pipes. It can also be used for making non-pressure pipes such as double-wall corrugated pipes, hollow-wall winding pipes, silicon-core pipes, agricultural irrigation pipes and aluminumplastics compound pipes. In addition, through reactive extrusion (silane cross-linking), it can be used for producing crosslinked polyethylene pipes (PEX) for supplying cold and hot water.

Grades and typical value

HDPE double-wall corrugated pipe is a new type of lightweight pipe made of high-density polyethylene. It has the characteristics of light weight, high pressure resistance, good toughness, fast construction and long life, etc. Its excellent wall structure design greatly reduces the cost compared with pipes of other structures. And because the connection is convenient and reliable, it has been widely used at home and abroad. Lots of replacement concrete pipe and cast iron pipe.

Different values of the ring stiffness represent different external pressure load resistance of the pipe. What we need to know is that the most important thing is the selection of the ring stiffness value, which also determines whether the pipe can operate safely and smoothly in the construction. So we must pay special attention to it. As we know, for pipes such as HDPE double-wall bellows, the ring stiffness in outdoor drainage engineering is very important. Too high is not good, too low is not good, too high will cause waste of raw materials and increase the cost, too low is likely to cause damage to the pipeline due to deformation