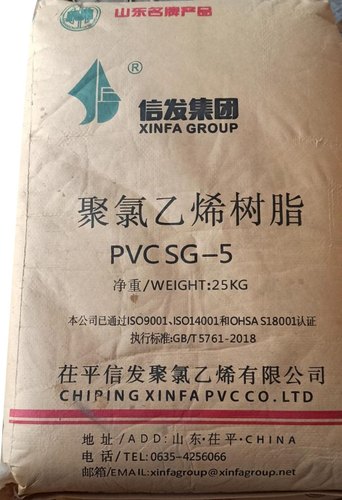

Xinfa PVC resin

Xinfa PVC resin,

PVC resin SG1-SG7,

PVC (PolyVinylChloride), according to the hardness and properties of the material generally have 7 levels (SG1-SG7), the density of 1.4 g/cm³ or so. The following SG4 is generally soft products, which need to add a large amount of plasticizer when forming, mainly used for the production of artificial leather, wire and cable insulation, seals and so on. SG5 and above are hard products, mainly used to make a variety of pipes, such as drainage, electrical, postal and telecommunications pipes and pipe fittings, a variety of plates, sheets, profiles, etc. PVC molding shrinkage rate of 0.6-1.5%, has good mechanical properties, excellent electrical properties, and has self-quenching, acid and alkali resistance is very strong, good chemical stability, low price, is a very widely used general plastic. However, because its use temperature is not high, the highest is about 80 ° C, hindering its development.

Product detail

PVC is an acronym for polyvinyl chloride. A resin is a material often used in the production of plastics and rubbers. PVC resin is a white powder commonly used to produce thermoplastics. It is a synthetic material widely used in the world today. Polyvinyl chloride resin has outstanding characteristics such as abundant raw materials, mature manufacturing technology, low price, and wide range of uses. It is easy to process and can be processed by molding, laminating, injection molding, extrusion, calendering, blow molding and other methods. With good physical and chemical properties, it is widely used in industry, construction, agriculture, daily life, packaging, electricity, public utilities, and other fields. PVC resins generally have high chemical resistance. It is very strong and resistant to water and abrasion. Polyvinyl chloride resin (PVC) can be processed into various plastic products. PVC is a lightweight, inexpensive, and environmentally friendly plastics.

Features

PVC is one of the most widely used thermoplastic resins. It can be used to make products with high hardness and strength, such as pipes and fittings, profiled doors, windows and packaging sheets. It can also make soft products, such as films, sheets, electrical wires and cables, floorboards and synthetic leather, by addition of plasticizers

Specification

| PVC RESIN SG3 | |||||

|

Item |

Specification |

Measured Value |

|||

| Superior Grade | First Grade | Qualifide Grade | |||

| Viscosity Number,ML/G | 127~135 | 127~135 | 127~135 | 131 | |

| Mass fraction of Volatile Matter (including water),%≤ | 0.3 | 0.4 | 0.5 | 0.2 | |

| Apparent Density,g/mL,≥ | 0.45 | 0.42 | 0.4 | 0.51 | |

| Reduce on Sieve,% | 250umSieve Mesh ≤Sieve, | 1.6 | 2 | 8 | 0.9 |

| 63umSieve Mesh ≥Sieve, | 97 | 90 | 85 | 99 | |

| “Fish Eye”/400cm²≤ | 20 | 30 | 60 | 10 | |

| 100g Resin Plasticizer Absorption,g≥ | 26 | 25 | 23 | 27 | |

| Whiteness(160℃,10min),%≥ | 78 | 75 | 70 | 83 | |

| Impurity Particle Number ≤ | 16 | 30 | 60 | 12 | |

| Conductivity of Water Extract,uS/cm.g≤ | 5 | 5 | —— | 0.6 | |

| Residual Vinyl Chloride Monomer Content,ug/g≤ | 5 | 5 | 10 | 1.6 | |

| PVC RESIN SG5 | |||||

| Grade | Specification |

Measured Value |

|||

| Specification | Superior Grade | First Grade | Qualifide Grade | ||

| Item | |||||

| Viscosity Number,ML/G | 118~107 | 111.24 | |||

| Impurity Particle Number ≤ | 16 | 30 | 80 | 16 | |

| Mass fraction of Volatile Matter (including water),%≤ | 0.4 | 0.4 | 0.5 | 0.4 | |

| Apparent Density,g/mL,≥ | 0.48 | 0.45 | 0.42 | 0.519 | |

| Reduce on Sieve,% | 250umSieve Mesh ≤Sieve, | 2 | 2 | 8 | 0.9 |

| 63umSieve Mesh ≥Sieve, | 95 | 90 | 85 | 98 | |

| “Fish Eye”/400cm²≤ | 20 | 40 | 90 | 8 | |

| 100g Resin Plasticizer Absorption,g≥ | 19 | 17 | —— | 22.28 | |

| Whiteness(160℃,10min),%≥ | 78 | 75 | 70 | 81.39 | |

| Conductivity of Water Extract,uS/cm.g≤ | —— | —— | —— | —— | |

| Residual Vinyl Chloride Monomer Content,ug/g≤ | 5 | 10 | 30 | 1 | |

| PVC RESIN SG8 | ||

| Item | Specification | |

| Viscosity Number,ML/G | 73-86 | |

| Impurity Particle Number ≤ | 20 | |

| Mass fraction of Volatile Matter (including water),%≤ | 0.4 | |

| Apparent Density,g/mL,≥ | 0.52 | |

|

Reduce on Sieve,% |

250umSieve Mesh ≤Sieve, | 1.6 |

| 63umSieve Mesh ≥Sieve, | 97 | |

| “Fish Eye”/400cm²≤ | 30 | |

| 100g Resin Plasticizer Absorption,g≥ | 12 | |

| Whiteness(160℃,10min),%≥ | 75 | |

| Residual Vinyl Chloride Monomer Content,mg/l≤ | 5 | |

Application

PVC profile

Profiles and profiles are the largest areas of PVC consumption in my country, accounting for about 25% of the total PVC consumption. They are mainly used to make doors and windows and energy-saving materials, and their applications are still increasing significantly across the country.

PVC pipe

Among many polyvinyl chloride products, polyvinyl chloride pipes are its second-largest consumption area, accounting for about 20% of its consumption. In my country, PVC pipes are developed earlier than PE pipes and PP pipes, with more varieties, excellent performance, and a wide range of applications, and occupy an important position in the market.

PVC film

The consumption of PVC in the field of PVC film ranks third, accounting for about 10%. After PVC is mixed with additives and plasticized, a three-roll or four-roll calendar is used to make a transparent or colored film with a specified thickness. The film is processed in this way to become a calendered film. It can also be cut and heat-sealed to process packaging bags, raincoats, tablecloths, curtains, inflatable toys, etc. The wide transparent film can be used for greenhouses, plastic greenhouses, and mulch films. The biaxially stretched film has the characteristics of heat shrinkage, which can be used for shrink packaging

PVC hard materials and plates

Stabilizers, lubricants, and fillers are added to PVC. After mixing, the extruder can be used to extrude hard pipes, special-shaped pipes, and corrugated pipes of various calibers, which can be used as sewer pipes, drinking water pipes, wire casings, or staircase handrails. . The calendered sheets are overlapped and hot-pressed to make hard plates of various thicknesses. The plate can be cut into the required shape, and then welded with hot air with a PVC welding rod to form various chemical resistant storage tanks, air ducts, and containers.

PVC general soft product

The extruder can be used to squeeze into hoses, cables, wires, etc.; the injection molding machine can be used with various molds to make plastic sandals, shoe soles, slippers, toys, auto parts, etc.

PVC packaging materials

Polyvinyl chloride products are mainly used for packaging in various containers, films, and rigid sheets. PVC containers mainly produce bottles of mineral water, beverages, and cosmetics, as well as packaging for refined oil. PVC film can be used to co-extrude with other polymers to produce low-cost laminates and transparent products with good barrier properties. Polyvinyl chloride film can also be used for stretch or heat shrink packaging for packaging mattresses, cloth, toys, and industrial goods.

PVC siding and floor

Polyvinyl chloride wall panels are mainly used to replace aluminum wall panels. Except for a part of PVC resin, the other components of PVC floor tiles are recycled materials, adhesives, fillers, and other components. They are mainly used on the ground of airport terminal buildings and other hard ground.

Polyvinyl Chloride Consumer Goods

Luggage bags are traditional products made by the processing of polyvinyl chloride. Polyvinyl chloride is used to make various imitation leathers, which are used in luggage bags and sports products such as basketball, football, and rugby. It can also be used to make belts for uniforms and special protective equipment. Polyvinyl chloride fabrics for clothing are generally absorbent fabrics (no need to be coated), such as ponchos, baby pants, imitation leather jackets, and various rain boots. Polyvinyl chloride is used in many sports and entertainment products, such as toys, records, and sports goods. Polyvinyl chloride toys and sports goods have a large growth rate. They have an advantage due to their low production cost and easy molding.

PVC coated products

Artificial leather with backing is made by coating PVC paste on cloth or paper, and then plasticizing it at a temperature above 100°C. It can also be formed by calendering PVC and additives into a film and then pressing it with the substrate. Artificial leather without a substrate is directly calendered by a calendar into a soft sheet of a certain thickness, and then the pattern can be pressed. Artificial leather can be used to make suitcases, purses, book covers, sofas, and car cushions, etc., as well as floor leather, used as floor coverings for buildings.

PVC foam products

When mixing soft PVC, add an appropriate amount of foaming agent to form a sheet, which is foamed into foam plastic, which can be used as foam slippers, sandals, insoles, and shock-proof cushioning packaging materials. The extruder can also be used to form low-foamed hard PVC boards and profiles, which can replace wood and is a new type of building material.

PVC transparent sheet

The impact modifier and organotin stabilizer are added to PVC, and it becomes a transparent sheet after mixing, plasticizing and calendering. Thermoforming can be made into thin-walled transparent containers or used for vacuum blister packaging. It is an excellent packaging material and decorative material.

Other

Doors and windows are assembled with hard special-shaped materials. In some countries, it has occupied the door and window market together with wooden doors, windows, aluminum windows, etc.; wood-like materials, steel-based building materials (northern, seaside); hollow containers.

Packaging

(1) Packing : 25kg net/pp bag, or kraft paper bag .

(2) Loading quantity : 680Bags/20′container, 17MT/20′container .

(3) Loading quantity : 1120Bags/40′container, 28MT/40′container .