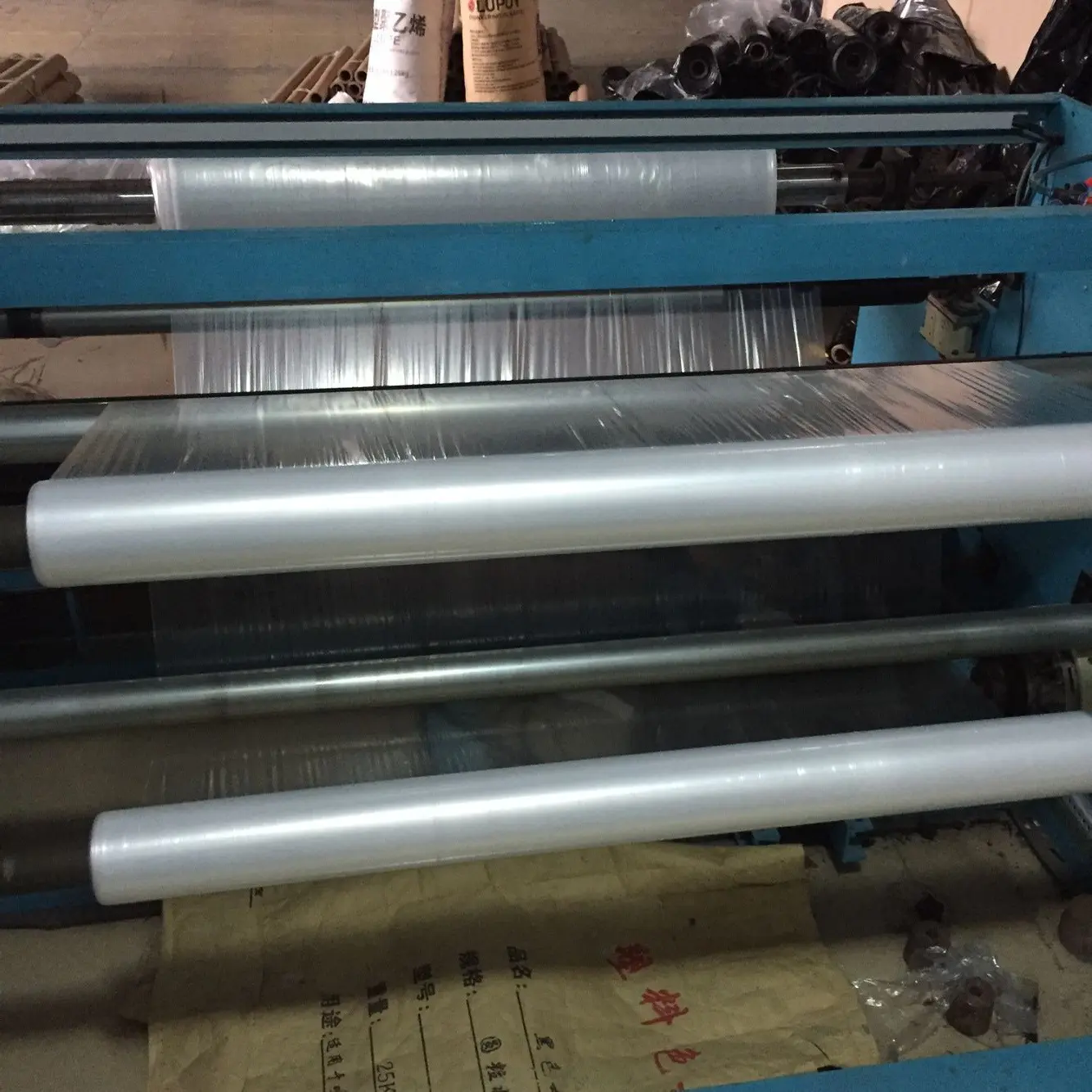

HDPE film grade

HDPE film grade,

HDPE for membrane, HDPE resin for film production,

High density polyethylene resin is non dangerous goods. Ecru granule or powder, free from mechanical impurities. The granule is cylindrical granule and packed in polypropylene woven bag with inner coating. The environment should be kept clean and dry during transportation and loading and unloading.

HDPE film grade has excellent physical properties, good processability, high mechanical strength and good stainability, printability and sealability. The resin is resistant to moisture, oil and chemical corrosion and has excellent high-speed processing properties.

Application

HDPE film grade is widely used in the production of T-shirt bags, shopping bags, food bags, garbage bags, packaging bags, industrial lining and multilayer film. In recent years, the resin has been increasingly used in beverage and medicine packaging, hot filling packaging and fresh produce packaging. The resin can also be used in the production of anti-seepage film used in hydraulic engineering .

Features

Ecru granule or powder, free from mechanical impurities.Ecru granule or powder, free from mechanical impurities.

Parameters

HDPE film is also known as High Density Polyethylene film, HDPE geomembrane and HDPE Impermeable membrane. Its English name is “High Density Polyethylene Impermeable membrane”, short for “HDPE Film”. HDPE film is a plastic coil composed of HDPE, its HDPE is a kind of high crystallinity, non-polar thermoplastic resin. The appearance of the original HDPE is milky white, a certain degree of translucency in thin section. PE has excellent resistance to most domestic and industrial chemicals. Certain types of chemicals can cause chemical corrosion, such as corrosive oxidants (concentrated nitric acid), aromatic hydrocarbons (xylene) and halogenated hydrocarbons (carbon tetrachloride). The polymer is non-hygroscopic and has good steam resistance. HDPE has good anti-corrosion performance, electrical performance, moisture-proof performance, anti-leakage performance, high tensile strength, so it is very suitable for wire and cable, engineering impervious, breeding impervious, oil tank impervious, basement impervious, artificial lake impervious and other fields. HDPE film has excellent impact resistance, so at room temperature and even at -40F low temperature. HDPE film is polymer non-toxic, tasteless, odorless white particles, melting point is about 110℃-130℃, the relative density of 0.918 — 0.965; It has good heat and cold resistance. Good chemical stability, with high rigidity and toughness, good mechanical strength, environmental stress cracking resistance and tear resistance performance, with the rise of density, mechanical properties and barrier properties will be improved, heat resistance, and tensile strength is higher; Resistant to acid, alkali, organic solvents and other corrosion.