Because pvc resin has good physical, chemical, electrical, flame retardant performance, in the 1930s and 40s, foreign began to use soft PVC as the insulation material for wire, the development and application of PVC cable material in China began in the 1950s. With the improvement of production capacity of PVC resin, plasticizer and industrial additives and the promotion and application of new varieties, the cable industry has a qualitative leap.

In the 21st century, with the enhancement of human environmental awareness and people’s attention to their own health, environmental issues have become the focus of human society. Many countries, regions and organizations have formulated strict standards and regulations to limit the use of harmful substances, especially RolS and REACH regulations. Looking for new methods and new processes, improve the utilization rate of resources, adapt to the requirements of environmental protection laws and regulations, environmental protection PVC cable materials emerged at the moment, and quickly become one of the themes of the current PVC cable materials development.

The increasing change and expansion of the market demand for wire and cable (referred to as cable), as well as the in-depth study of various new additives (such as flame retardant additives, smoke suppressor), promote the promotion and application of new technologies, new materials and new products of PVC materials. In a large amount of organic material (such as plastic, rubber) used in the cable industry, the amount of PVC cable material is the first organic material in our country.

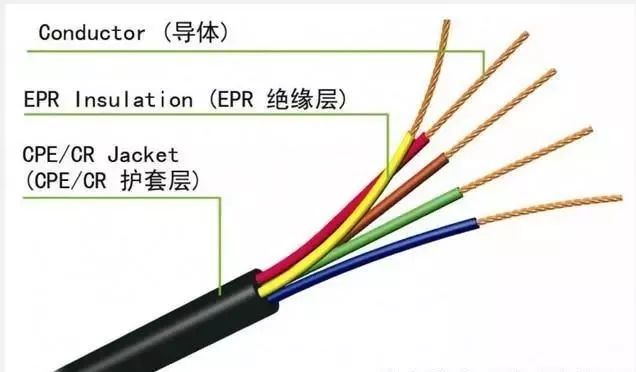

PVC cable material is composed of polyvinyl chloride resin, stabilizer, plasticizer, filler, lubricant, antioxidant, colorant and so on.

PVC plastic because of its flammability, oil resistance, corona resistance, chemical corrosion resistance and good water resistance, so it is also widely used as a protective material for wires and cables. By adding special performance additives or modifiers, heat resistant (105℃), cold resistant, oil resistant, flame resistant, extra-soft and non-toxic PVC cable materials can be manufactured respectively to meet the needs of special wire and cable products.

By adding special performance additives or modifiers, heat resistant (105℃), cold resistant, oil resistant, flame resistant, extra-soft and non-toxic PVC cable materials can be manufactured respectively to meet the needs of special wire and cable products.

Polyvinyl chloride (PVC) plastic is a multi-component plastic, according to different conditions of use, by changing the variety and dosage of the complex agent, can be made of different varieties of PVC plastic for wire and cable. Polyvinyl chloride (PVC) cable plastic according to its use in wire and cable, can be divided into insulation level cable material and protective level cable material. Protection level requires good heat resistance, and insulation level requires good insulation.

Use classification

PVC cable materials can be divided into:

PVC insulated cable material

PVC sheathed cable material

Flame retardant PVC insulated cable material

Flame retardant PVC sheathed cable material

PVC elastomer cable material

PVC outdoor overhead insulated cable

Post time: Aug-11-2022