PVC is synthesized from vinyl chloride by free radical polymerization. By suspension polymerization, emulsion polymerization and bulk polymerization, suspension polymerization is the main method, accounting for about 80% of the total PVC production. In the industry, PVC production process is generally based on the method of obtaining vinyl chloride monomer to distinguish, can be divided into calcium carbide method, ethylene method and imported (EDC, VCM) monomer method (traditionally called ethylene method and imported monomer method). According to the different production methods, PVC powder is divided into: universal PVC resin, PVC resin with high degree of polymerization, crosslinking PVC resin. Universal PVC resin is formed by polymerization of vinyl chloride monomer under the action of initiator; PVC resin with high degree of polymerization refers to the resin formed by adding chain increasing agent in the polymerization system of vinyl chloride monomer; Crosslinked PVC resin is a resin which is polymerized by adding crosslinking agent containing diene and polyene in the polymerization system of vinyl chloride monomer.

Suspension polyvinyl chloride resin Current model:

Sg-1: K 77-75 average degree of polymerization

Sg-2: K 74-73 average degree of polymerization

Sg-3: K value 72-71 Average polymerization degree 1350-1250

Sg-4: K value 70-69 average degree of polymerization 1250-1150

Sg-5: K value 68-66 Average degree of polymerization 1100-1000

Sg-6: K value 65-63 Average degree of polymerization 950-850

Sg-7: K value 62-60 average degree of polymerization 850-750

Sg-8: K value 59-55 average degree of polymerization 750-650

Main applications:

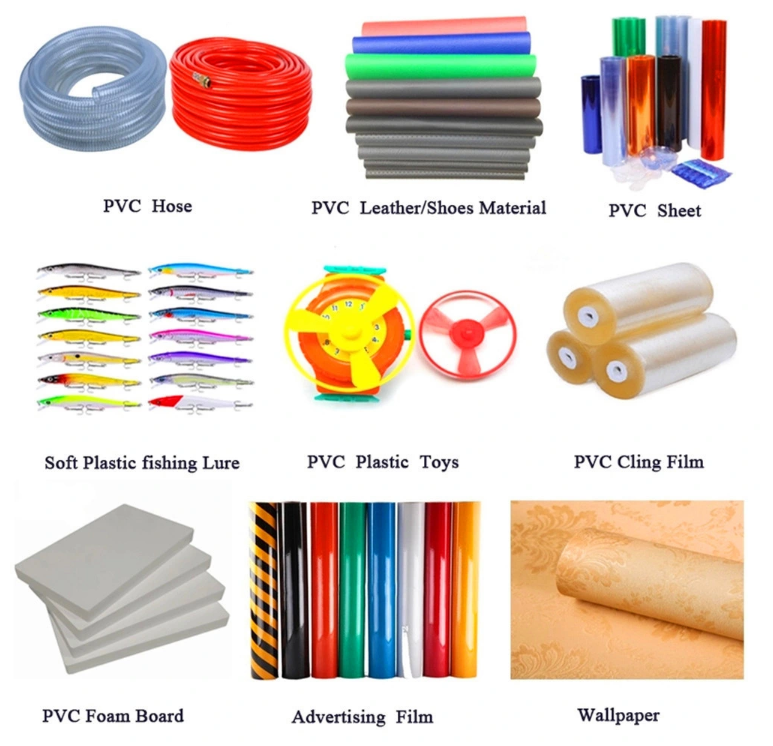

PVC resin can be processed into a variety of plastic products, according to its use can be divided into two categories of soft and hard products, mainly used in the production of transparent pieces, pipe fittings, gold cards, blood transfusion equipment, soft and hard pipes, plates, doors and Windows, profiles, films, electrical insulation materials, cable sheath, blood transfusion materials, etc.

1.PVC general soft and hard products – using extruder can be squeezed into soft and hard pipes, cables, wires, etc.; With THE injection molding machine and various molds, it can be made into plastic sandals, soles, slippers, toys, daily necessities and automobile and electrical accessories.

2 PVC rigid pipe and profile – relative to other plastics, PVC aging resistance is excellent, high impact strength and toughness, low price, suitable for drainage pipes and other construction pipe, and profile profile.

3 PVC film – PVC and additives mixed, plasticizing, the use of three or four roll rolling mechanism into a specified thickness of transparent or colored film, with this method processing film, become calendering film. Can also be cut, thermal processing packaging bags, raincoats, tablecloths, curtains, inflatable toys and so on. Wide transparent film can be used for greenhouse, plastic greenhouse and plastic film. After bidirectional stretching of the film, the property of heat shrinkage, can be used for shrink packaging.

4 PVC coated products – with the substrate of artificial leather is PVC confused on cloth or paper, and then in 100 degrees Celsius above plasticized. Can also be PVC and auxiliary calendering film, and then pressed together with the substrate. The artificial leather without substrate is directly calendered by the calendering machine into a certain thickness of soft sheet, and then pressed on the pattern. Artificial leather can be used to make suitcases, bags, book covers, sofas and car cushions, and floor leather, used as a building floor material.

5.PVC foam products – soft PVC mixing, add the right amount of foaming agent to do sheet material, foam molding for foam plastic, foam slippers, sandals, insoles, and shockproof buffer packaging materials. Also CAN USE extruder FOUNDATION into low foaming hard PVC sheet and profile, can replace wood trial, is a new type of building materials.

6 PVC transparent sheet – PVC add impact modifier and stabilizer, after mixing, plasticizing, calendering and become transparent sheet. The use of hot forming can be made into thin-walled transparent containers or used for vacuum blister packaging, is an excellent packaging materials and decorative materials.

7 PVC hard plate and plate – PVC stabilizer, lubricant and filler, after mixing, with extruder can be extruded various caliber of hard pipe, special-shaped pipe, bellows, used as a downpipe, drinking pipe, wire sleeve or stair handrail. Overlapping hot pressing of the calendered sheet can make hard sheets of various thicknesses. The plate can be cut into the desired shape, and then the use of PVC electrodes with hot air welding into a variety of chemical corrosion resistant storage tanks, air ducts and containers.

8.PVC other – doors and Windows are made of hard special-shaped materials. In some countries has been with wood doors and Windows aluminum Windows and other common doors and Windows market; Imitation wood materials, generation steel building materials (north, seaside); Hollow container.

Post time: Aug-08-2022