HDPE resin for Geomembrane

HDPE resin for Geomembrane,

HDPE resin film grade, Which kind of HDPE resin is used for Geomembrane,

High density polyethylene resin is non dangerous goods. Ecru granule or powder, free from mechanical impurities. The granule is cylindrical granule and packed in polypropylene woven bag with inner coating. The environment should be kept clean and dry during transportation and loading and unloading.

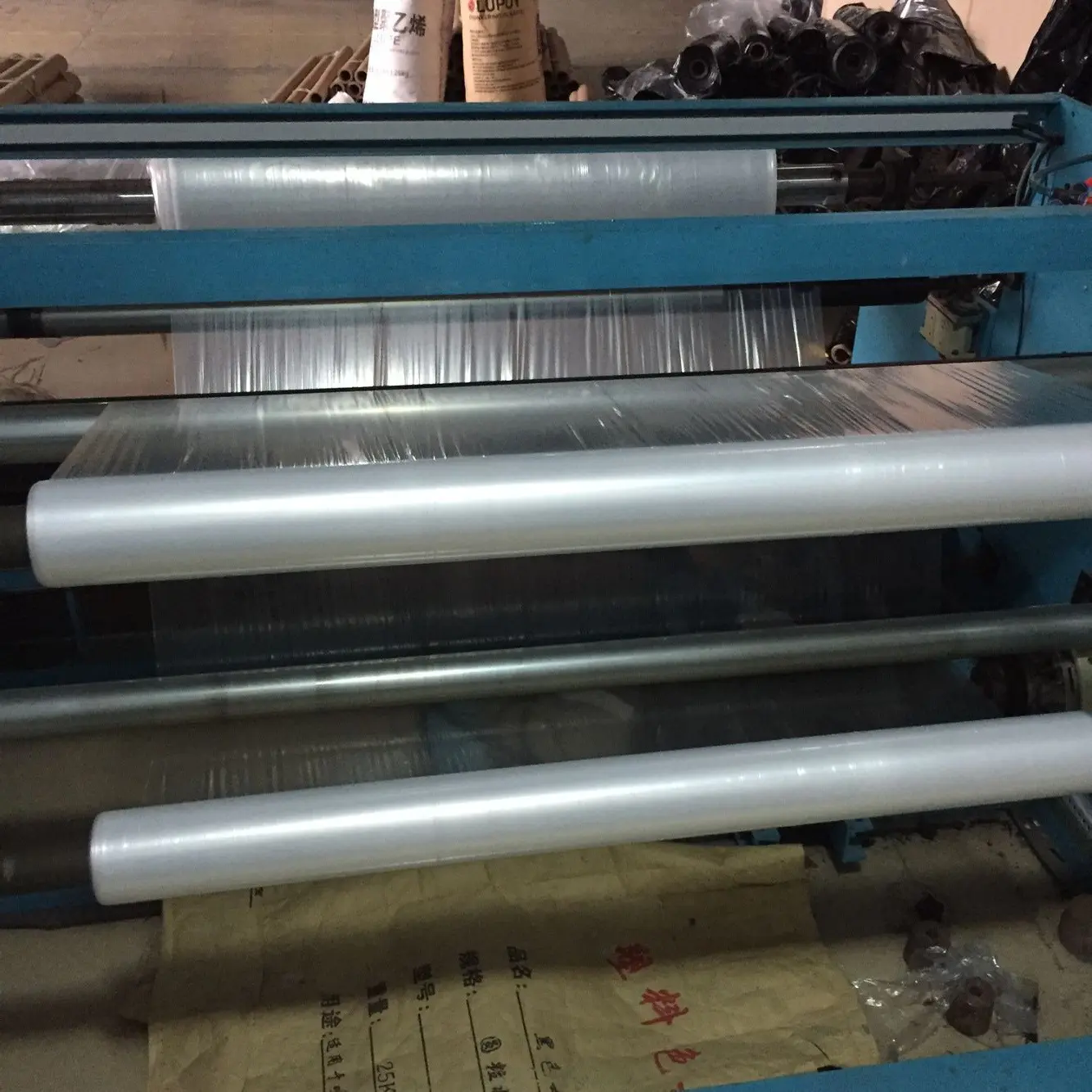

HDPE film grade has excellent physical properties, good processability, high mechanical strength and good stainability, printability and sealability. The resin is resistant to moisture, oil and chemical corrosion and has excellent high-speed processing properties.

Application

HDPE film grade is widely used in the production of T-shirt bags, shopping bags, food bags, garbage bags, packaging bags, industrial lining and multilayer film. In recent years, the resin has been increasingly used in beverage and medicine packaging, hot filling packaging and fresh produce packaging. The resin can also be used in the production of anti-seepage film used in hydraulic engineering .

Features

Ecru granule or powder, free from mechanical impurities.Ecru granule or powder, free from mechanical impurities.

Parameters

Geomembrane is a kind of good geomembrane, the permeability coefficient of geomembrane must be greater than 10 times that of soil, so in order to make the front head rise, under the action of penetration, in close to the geomembrane can carry small particle size in the geomembrane, this situation gradually develops away from the direction of geomembrane, The top layer is gradually formed by a certain thickness of thicker geotechnical particles. The particles are thicker and the permeability coefficient is larger, but can not block the movement of fine particles. Geomembrane manufacturers warp knitting compound, that is, the use of warp knitting binding line in the warp, weft yarn and geomembrane fiber layer through repeatedly, so that the three plaited as a body. Therefore, the warp-knitted composite geomembrane not only has the characteristics of high tensile strength, low elongation, but also has the waterproof performance of geomembrane. So warp-knitted composite geomembrane is a kind of anti-seepage material with reinforcement, isolation and protection. It is one of the most widely used geocomposite materials in the world today. After giving full play to the filtration function of the geomembrane, a natural filter layer is formed on the upstream side of the top surface, and the fine content of the natural filter layer is higher than that of the top layer, and the permeability is relatively low. As a result, it prevents the movement of fine soil particles in the adjacent natural soil layer, thereby preserving the soil. That’s how geomembranes work.

Zibo Junhai Chemical supply many kinds of HDPE resin,whats app:+86 15653357809